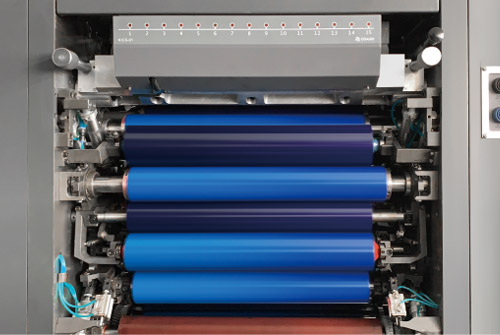

Heavy Offset Printing Unit

High quality heavy offset printing unit with well-designed inking system which can transfer ink fast & evenly, avoids gear mark and ghost image effectively. The printing quality can be highly improved.

| Model | ZP-520 | ZP-680 |

| Max. printing speed | 170m/min | 160m/min |

| Printing color | 4-12 Colors | 4-12 Colors |

| Max. printing width | 520mm | 680mm |

| Max. web width | 540mm | 700mm |

1. High-speed rotary offset printing machine (with sleeve technology) owns more than 20 national and international patents.

2. Continuous offset printing mode and variety printing sleeve technology makes fast printing speed and high printing quality.

3. The plate roller and the blanket roller adopt the air expansion sleeve type achieves short plate changing time, easy operation, and high efficiency.

4. The inking system and water system are automatically adjusted according to variable printing sleeve. Super inking system makes the inking move evenly, printing pressure more stable and easy adjusting.

5. Unwinder has automatic tension control and is equipped with web guider.

6. Printing tension controls automatically, the web passing smoothly even at high speed, stable printing tension ensures high-speed and high-precision printing.

7. This machine has the function of automatic pre-registration, automatic registration by photocell after set-up and second pass with registration.

8. Inline inspecting system can be installed according to user’s requirement.

9. Based on offset printing units, machine can combine with other functions such as flexo, gravure, cold stamping, hot stamping, die cutting, embossing and so on.

10. This machine is suitable for variable substrates, such as: self-adhesive paper, paper and unsupported film (BOPP, PET, PP, PVC, etc.).

Variable Printing Sleeve

Automatic Ink Control System

UV Dryer With Water Chiller

| Model | ZP-520 | ZP-680 |

| Max. printing speed | 170m/min | 160m/min |

| Printing color | 4-12 Colors | 4-12 Colors |

| Max. printing width | 520mm | 680mm |

| Max. web width | 540mm | 700mm |

| Printing repeat length | 381-686mm(15-27 inch) | 432-686mm(17-27 inch) |

| Max. unwinding dia. | 1000mm | 1000mm |

| Max. rewinding dia. | 1000mm | 1000mm |

| Dimensions(L×W×H) | 15.2m × 3.7m × 2.1m Unwinder + Flexo unit with cold stamping + 5 Offset units + Flexo(varnishing) + Die-cutting unit + Rewinder |

|

High quality heavy offset printing unit with well-designed inking system which can transfer ink fast & evenly, avoids gear mark and ghost image effectively. The printing quality can be highly improved.

When the printing job with different repeat length, just change both plate and blanket sleeve accordingly.The sleeve changing is very fast and efficient.

One-button setting, ink control is automatically, because of ink supply automation and precision, it improves the printing efficiency & quality, and reduces wastage.

One-button setting, ink control is automatically, because of ink supply automation and precision, it improves the printing efficiency & quality, and reduces wastage.

In order to print more shining, the flexo unit can do spot varnishing or full varnishing or drip off, can be installed according to user's requirement.

Cold stamping with registration and hologram transfer, can be installed according to user’s requirement.

Adopts magnetic roller, the printing and die-cutting can be finished at one time. It can be installed according to user's requirement.

Snowball type waste collecting device, matrix speed synchronizes to the printing speed.

Touch control panel, faster operating speed. main control with 15inch large touch screen, friendly design and easy operation; each printing unit equips with 7inch touch screen, can be operated independently and easily. Error alarms will be displayed instantly, which shortens the trouble shooting and repairing time greatly.

Touch control panel, faster operating speed. main control with 15inch large touch screen, friendly design and easy operation; each printing unit equips with 7inch touch screen, can be operated independently and easily. Error alarms will be displayed instantly, which shortens the trouble shooting and repairing time greatly.

What is the Label Flexo Printing Machine?Label flexo printing machine is a printing device that uses a rubber plate or rubber cylinder ...

Date:10-12 May Venue:Bangkok Thailand Booth No.:C22

Date:25-27 September Venue:Chicago

Learn More Information

About Our Products